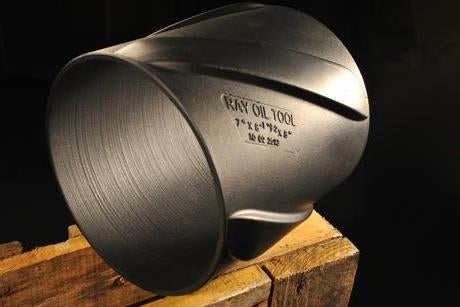

Duraslide® Low Friction Centraliser (Centralizer)

Previous field runs prove you can experience a minimised start-up torque and easier pipe rotation due to the entire centralizer (centraliser) being coated, 100%

|

|

Our Duraslide® coating is applied to the entire centralizer body, ID, and OD, then baked on at high temperature to ensure the coatings durability required downhole.

We now offer you a centralizer with a proven track record in reducing the coefficiency of friction helping you get to bottom faster - contact us for more information.

Duraslide® Coating the entire Inside Diameter enables a centralizer to rotate more freely around the casing. This develops low rotational friction that enables a reduced running force as it rotates,

- Drag is reduced when running from cased hole sections through into open hole

- Reduced startup torque when rotating liners

- Enhanced cleanup and cement placement property.

Ten Benefits of DURASLIDE® Coating

DURASLIDE® coatings provide:

|

Like to know more?

Contact a Ray Oil Tool Representative for more product information, prices & availability today.